Air Handling Units (AHU)-HVAC R -Orient Marketing

Disinfection Walk Through Gate For COVID-19

May 9, 2020

Expansion Tanks in Higher HVAC R System

May 26, 2020Air Handling Unit

Air handling unit from ANSI/AHRI Standard 430-2009 states that it is:

“A factory-made encased assembly consisting of a fan or fans and other necessary equipment to perform one or more of the functions of circulating, cleaning, heating, cooling, humidifying, dehumidifying and mixing of air….”

The Air Handling Unit (AHU) is used to control the following parameters of the space:

- Temperature

- Humidity

- Air Movement

- Air Cleanliness

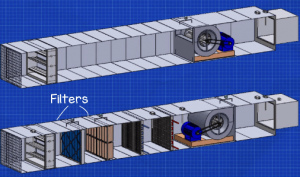

Components:

It has following components:

- Housing

- Fan

- Cooling Coils

- Filters

- Hepa filters

- Bag Filters

- Electrostatic Filters

- Humidifiers

- Mixing Box

Introduction To Air Handling Units(AHU):

They are usually located in the basement, on the roof or on the floors of a building. AHU’s will serve a specified area or zone within a building such as the east side, or floors 1 – 10 or perhaps a single purpose such as just the buildings toilets. Therefore, it’s very common to find multiple AHU’s around a building.

Working of Air Handling Units:

Air handling units’ condition and distribute air within a building. They take fresh ambient air from outside, clean it, heat it or cool it, maybe humidify it and then force it through some duct work around to the designed areas within a building. Most units will have an additional duct run to then pull the used dirty air out of the rooms, back to the AHU, where a fan will discharge it back to atmosphere. Some of this return air might be recirculated back into the fresh air supply to save energy

At the inlet of the fresh air housing and the discharge of the return air housing we have some dampers. The dampers are multiple sheets of metal which can rotate. They can close to prevent air from entering or exiting, they can open to fully allow air in or out, and it can also vary their position somewhere in between to restrict the amount of air that can enter or exit.

After the dampers we’ll have some filters. These are there to try and catch all the dirt and dust etc from entering the AHU and the building. If we don’t have these filters the dust is going to build up inside the duct work and within the mechanical equipment, it’s also going to enter the building and be breathed in by the occupants as well as make the building dirty. So, we want to remove as much of this as possible. Across each bank of filters, we’ll have a pressure sensor. This will measure how dirty the filters are and warn the engineers when it’s time to replace the filters. As the filters pickup dirt, the amount of air that can flow through is restricted and this causes a pressure drop across the filters. Typically, we have some panel filters or pre-filters to catch the largest dust particles. Then we have some bag filters to catch the smaller dust particles.

The next thing we’ll find are the cooling and heating coils. These are there to heat or cool the air. The air temperature of the supply air is measured as it leaves the AHU and enters the duct work. This needs to be at a designed temperature to keep the people inside the building comfortable, this designed temperature is called the set point temperature. If the air temperature is below this value the heating coil will add heat to increase the air temperature and bring it up to set point. If the air is too hot then the cooling coil will remove heat to lower the air temperature and reach the set point.

Conclusion:

Through the above explanation you might be understood about Air Handling Units (AHU). It is specially used in Pharmaceutical industries.

We are the manufacturer of Air Handling Units (AHU).Our AHU are of best quality and fully controlled systems . By combining these components and our 29 years experience we manufacture these air handling units .